Embossed hoodie have taken the fashion world by storm, captivating consumers with their distinctive raised designs and textures. Whether you’re a brand, distributor, or individual seeking to create your own line, understanding the intricacies of the embossed hoodie production process is essential. This knowledge empowers you to collaborate effectively with manufacturers and ensure the creation of high-quality embossed hoodies that meet your expectations. Let’s delve into the key stages of this process:

Here’s a breakdown of the key stages involved in creating embossed hoodies:

1. Design and Artwork Preparation:

- Concept and Design: Work closely with your clients to understand their vision for the embossed design. This includes elements like the logo, artwork, or text they want to be embossed, as well as the desired placement on the hoodie.

- Digitization: Convert the design into a digital format suitable for the embossing machine. This often involves using specialized software to create a 3D model of the design.

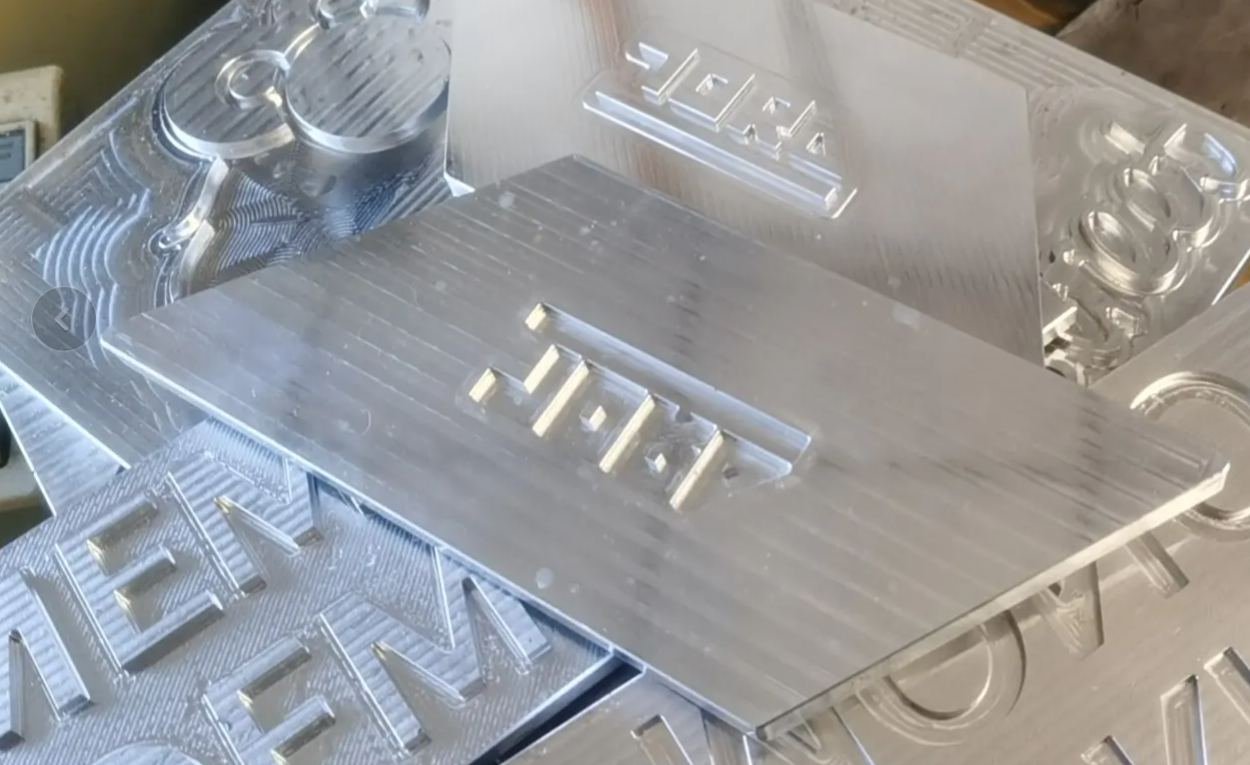

- Mold Creation: Based on the digital design, a mold is created. This mold will be used to press the design onto the fabric during the embossing process. Therefore, the sample price of some manufacturers will be relatively high.

2. Custom Embossed Hoodie Fabric Selection and Preparation:

- Choosing the Right Fabric: The type of fabric plays a significant role in the quality and appearance of the final product. Heavier fabrics like fleece or French terry work well for embossing as they provide a stable base for the raised design. So This is also the reason why some hoodies have poor embossing effect and the embossing effect disappears after cleaning once or twice.

- Prepping the Fabric: Before proceeding to the embossing stage, it’s essential to prep the fabric. Ensure the fabric is clean and free of wrinkles. This preliminary step helps achieve a crisp and even embossing result. This helps achieve a crisp and even embossing result. If the fabric has wrinkles, the embossing result will be very poor, and the fabric will become a defective product.

3. Embossing Process:

- Heat and Pressure: The embossing machine places the chosen fabric on the lower plate, with the mold positioned on top(There is also a method where the mold is placed underneath and the fabric is on top.). Then, the machine applies heat and pressure, pressing the design into the fabric and creating the raised effect.

- Precision and Control: Maintaining consistent heat and pressure throughout the process is crucial for achieving uniform embossing across the entire design.This meticulous control ensures a flawless and professional finish.

4. Custom Embossed Hoodie Quality Control and Finishing:

- Inspection: After the embossing process, we Take the time to carefully examine each embossed hoodie, ensuring the design is clear, well-defined, and free from any defects. This quality control step is essential for delivering a top-notch product.

- Cleaning and Packaging: After the embossing process, we remove any excess material or debris, leaving your hoodies pristine. Finally, we carefully fold and package them according to your exact specifications, ready to impress.

Additional Considerations:

- Embossing Techniques: Explore different embossing techniques like blind embossing (no color added), foil embossing (adding metallic or colored foil), or combination embossing (combining embossing with printing) to offer a variety of options to your clients.

- Customization: Provide customization options for clients to personalize their hoodies with individual names, numbers, or unique designs.

- Sustainability: Consider using eco-friendly fabrics and production methods to appeal to environmentally conscious consumers.

To excel in the embossed hoodie market, collaborate with reputable manufacturers and suppliers. Master the production process, prioritize quality, customization, and sustainability. This ensures unique, desirable products that meet fashion industry demands. Attention to detail and commitment to excellence are crucial for success in this competitive market.